ACE-H3048 Fully Automatic Hydrocarbon Vacuum Cleaning & Drying Machine

Hydrocarbon cleaning is the ideal choice to replace ODS material cleaning. It can effectively complete the cleaning and drying of precision parts, expecially all type small parts such as iron, steel, aluminum and copper etc.

Features

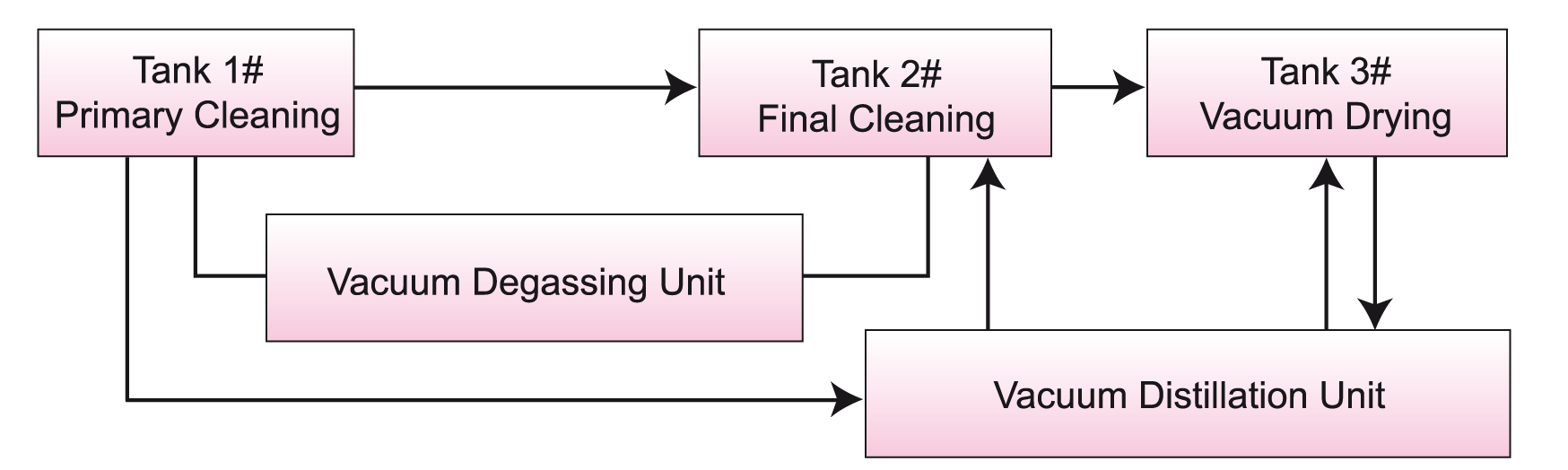

- Vacuum Deaerating Unit

Normally liquid has certain content of gas under normal pressure, which prevents a better cleaning result in ultrasonic wave. Vacuum Deaerating Unit separates gas in slits, blind holes, and tiny bores form liquid and articles to be cleaned, and enables non-gas presence ultrasonic cleaning which guarantees finally cleaning degree and effect.

- Vacuum Cleaning and Drying System

In vacuum state liquid temperature is higher than boiling point and cleaning ability is strong. Cleaning liquid is quickly abstracted and in vaccum state the process parts are easier to get dried.

- Vacuum Distillation Recovery System

It has a function of distillation recovery, concentration and automatically exclude waste oil. Dissolovent that contains large amount dirty oil may be distilled and recovered. It has several safety measures i.e. indirect heating, over heating prevention, anti-explosion motor, air segregation etc.

Cleaning Flow

Related

ACE - 4R Series Ultrasonic Vapour Degreaser

Apply non-flammable organic solvent such as chlorylene, methyl chloroform N-Propyl Bromide. It has following functions: thermo cleaning, supersonic cleaning, steaming cleaning, frozen drying, cleaning solvent recycle, It may be used clean away turpentine on electronic parts or printed circuit, grease on parts of precise machine, clock buckle, clock cover, lamp, glass products etc.

ACE - 5R Series Ultrasonic Vapour Degreaser

Apply non-flammable organic solvent such as chlorylene, methyl chloroform N-Propyl Bromide. It has following functions: thermo cleaning, supersonic cleaning, steaming cleaning, frozen drying, cleaning solvent recycle, It may be used clean away turpentine on electronic parts or printed circuit, grease on parts of precise machine, clock buckle, clock cover, lamp, glass products etc.